Challenge

The original equipment manufacturer (OEM) required a repair support partner to service in-country (UK) repair requirements and to increase the speed of turnaround time for a major fixed-line operator. Various faults were present across the estate, with limited information on the root cause, as the parts were typically known to be durable and reliable.

Diagnosis

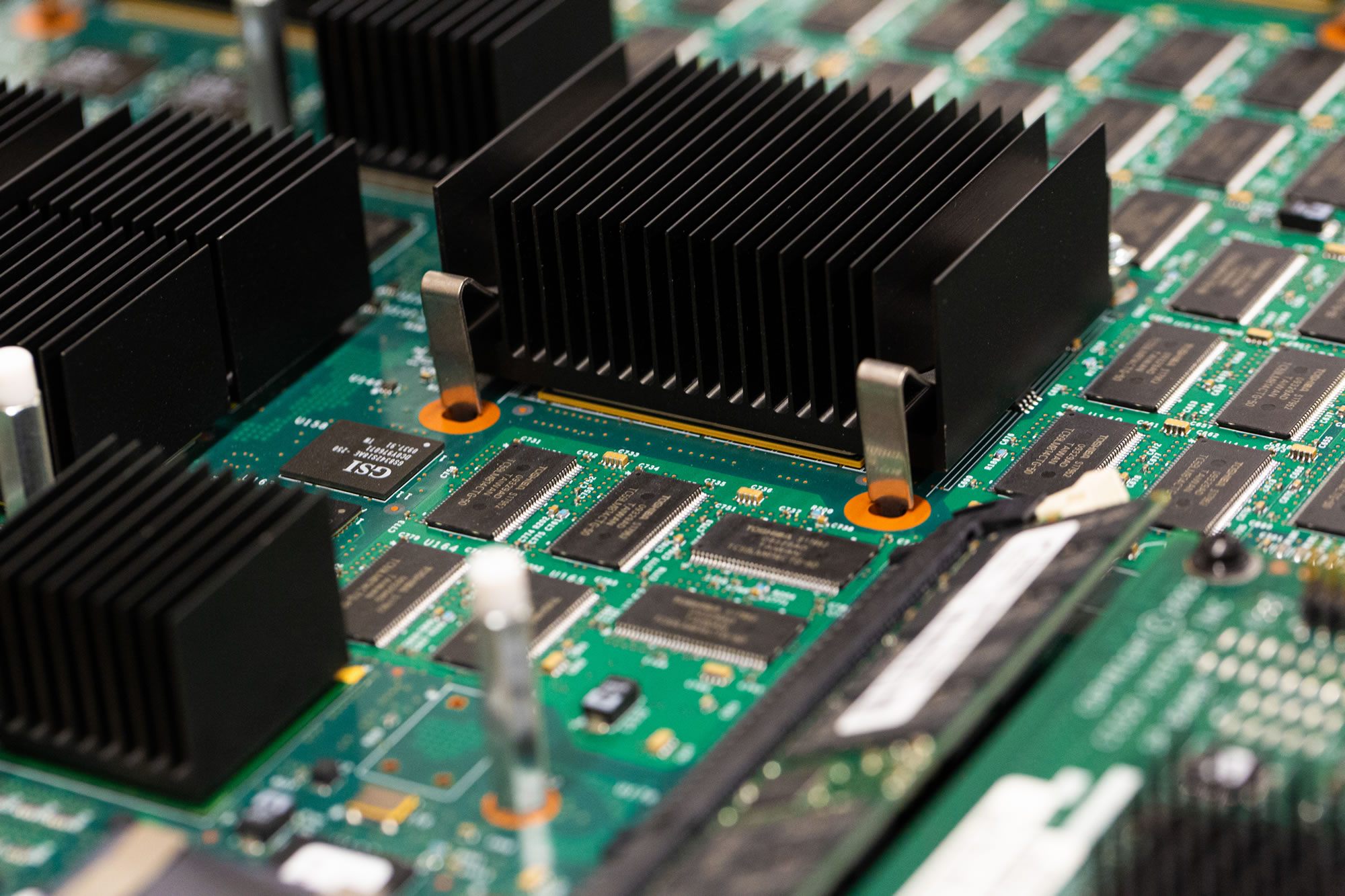

The OEM partnered with TXO to build a bespoke test bed that mirrored the layout of the network for simulation and testing. Software and gold reference systems were also provided to demonstrate a high working standard. Lab teams focused on POTS cards and cross-connected them in the same shelf to simulate voice calls and dial connectivity. Functional tests were conducted on the cards to identify link-up faults. It transpired that the boards were not booting up correctly due to multiple integrated circuit (IC) failures.

Solution

TXO identified a range of replacement ICs that were more durable and suited to the requirements of the boards, giving the devices a new lease of life for further use in the field. The new components were carefully attached and integrated into the existing board, with the previous versions being meticulously removed. Extensive soak tests were conducted post new part attachment to ensure like-for-like functionality against the gold unit in the lab. Once tested, the parts were re-wrapped and ringfenced for immediate customer collection.

Results

TXO developed a new IC feature set to replace failing components on the boards, resulting in a full repair and extended lifetime of the device moving forward, returning it to a new level of functionality. The bespoke test bed created for this purpose is also available for future use, ensuring a faster turnaround if other cards become faulty.

- Customised testing environment: By creating a bespoke test bed, TXO was able to simulate real-world conditions, leading to a precise diagnosis and effective solution.

- Enhanced component durability: The identification and integration of more durable ICs significantly extended the lifespan of the boards.

- Efficient turnaround: The strategic approach to testing and repair ensured a swift turnaround time, enhancing operational efficiency for the client.

- Sustainable practice: This solution aligns with TXO’s commitment to the circular economy, reducing waste and promoting the reuse of telecom network equipment.

This case study exemplifies TXO’s innovative approach to solving complex repair challenges, underpinned by our commitment to sustainability and operational excellence.

You might be interested in:

TXO named finalist for the Connected Britain Sustainability Award 2025

We’re thrilled to announce that TXO is a finalist for the 2025 Connected Britain Sustainability Award! This recognition celebrates the impact we’re making in helping organisations reduce waste, extend asset lifecycles, and adopt more sustainable, circular practices across the technology supply chain.

Planning your copper-to-fibre transition? Here’s how to do it sustainably

As telecom operators across the globe accelerate their transition from copper to fibre, the industry faces a critical question: how can we scale fibre networks in a way that’s both cost-effective and sustainable? TXO’s CTO, John Teasdale, joined a panel of global experts in a World Broadband Association (WBBA) webinar to address this challenge.

Bridging the digital divide: how sustainable tech practices can drive digital inclusion

As the world races ahead with digital innovation, millions remain unconnected. Bridging the digital divide isn’t just a moral imperative, it’s a strategic one. By embedding sustainability into telecom and tech infrastructure, we can drive both environmental progress and digital inclusion.